Thin film batteries are similar to lithium-ion batteries, but they are composed of thin materials, some only nanometers or micrometers thick, which allow the finished battery to be just millimeters thick. These have been developed and advanced for the most part of the last ten years. These can be easily fabricated. They are flexible and non-breakable. Cells or batteries made from thin films can double up as building materials.

Lithium-ion batteries store chemical energy in reactive chemicals at the anodes and cathodes of a cell. Typically, anodes and cathodes exchange lithium (Li+) ions through a fluid electrolyte that passes through a porous separator which prevents direct contact between the anode and cathode. Such contact would lead to an internal short circuit and a potentially hazardous uncontrolled reaction. Electric current is usually carried by conductive collectors at the anodes and cathodes to and from the negative and positive terminals of the cell (respectively). In a thin-film lithium battery the electrolyte is solid and the other components are deposited in layers on a substrate. In some designs, the solid electrolyte also serves as a separator.

These batteries consist of a substrate, electrolyte, current collector, anode, cathode, and a charge separator. There has been much research into the determination of the most effective components for this type of battery. It has been shown recently that even ordinary printer paper can be used as a charge separator and a substrate. The term “thin film” is derived from the fact that the deposited films are of the order of a few micrometers in thickness compared with the 10 to 50 micrometers for thick film. Often, thin film conductors are plated to improve conductivity. Thin film has the advantages of tighter absolute and ratio tolerances and more environmentally stable components with lower noise and tighter TCR than thick film. Thin-film printing technology is being used to apply solid-state lithium polymers to a variety of substrates to create unique batteries for specialized applications. Thin-film batteries can be deposited directly onto chips or chip packages in any shape or size.

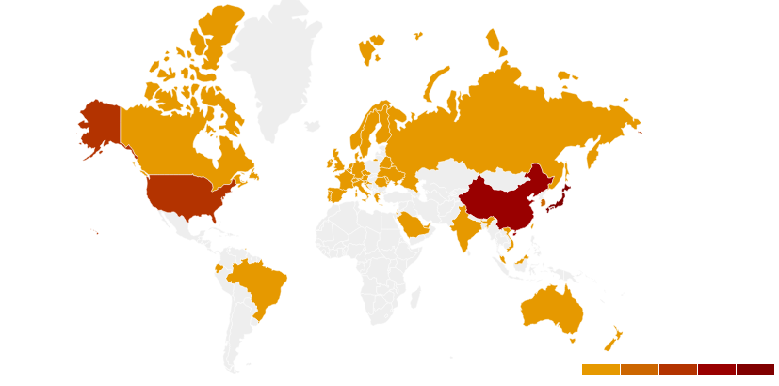

In terms of regional pockets where patent protection is being sought most frequently for these

technologies, Japan leads the count, followed by the USA and China. The basic distinction between thick film and thin film is the method of deposition of the metallization. In thick film, specially formulated pastes are applied and fired onto a substrate. The pastes are usually applied with a silk screen method and the substrate is of 96% alumina ceramic. Thin film technology is used wherever precision resistors are needed.