Energy harvesting materials for use in operating low power electronics have been an active area of interest for decades. Researchers introduced a methodology for determining the feasibility of in situ energy harvesting as a viable power source for a given low-power system and demonstrated that energy harvesting is an excellent way to extend the lifespan of low-power systems where power availability is the limiting factor. Although vibration harvesting has lower power density than solar and wind harvesting, it holds the advantages such as being less dependent on location, more self-contained, and largely maintenance free.

Energy harvesting materials are divided into three categories including piezoelectric, pyroelectric, and thermoelectric. Piezoelectric materials can transfer pressure force to electricity while thermoelectric and pyroelectric materials engender electricity by temperature gradient and alteration respectively.

Piezoelectric materials are one of the energy harvesting materials that can generate electricity during mechanical deformation and can be connected to an electrical load or storage device to harvest energy from mechanical vibrations. In other words, this kind of materials can transform mechanical energy such as pressure, vibration or force into electrical potential. Some properties of piezoelectric materials have made them vital in anthropogenic energy producing. Properties like high energy density, suitable electromechanical conversion efficiency, and their capability to be shaped as films, sheets and other flexible structures that can be incorporated unobtrusively into body wear further signify the importance of piezoelectric materials.

Thermoelectric materials are designed to be used in road transport, cars and lorries which will result in significant fuel savings. In 2009, Volkswagen reported that the thermoelectric generator of their prototype car produced 600W from crossing along a highway. The energy saving for their experiment was 5%, which is expected to be improved until now. Bahk et al. reviewed recent advances in the development of flexible thermoelectric materials and devices for wearable human body-heat energy harvesting applications. They identified that organic materials have shown great potential to be excellent thermoelectric materials for these applications with their own advantages in addition to very low thermal conductivity, i.e. flexibility, light weight, material abundance, and low-cost manufacturing. Also for sufficient power generation above 100 mW, a mm-level thickness of thermoelectric materials and a large device size are required.

It is proved that some crystals can be naturally electrically polarized by temperature change. This phenomenon is known as pyroelectricity. The primary advantage of thermoelectric energy conversion techniques is that these devices only require a steady state temperature gradient to operate and consequently possess no moving parts that can limit device reliability and life. The potential of these materials in transforming thermal wavering into electrical power has been less explored.

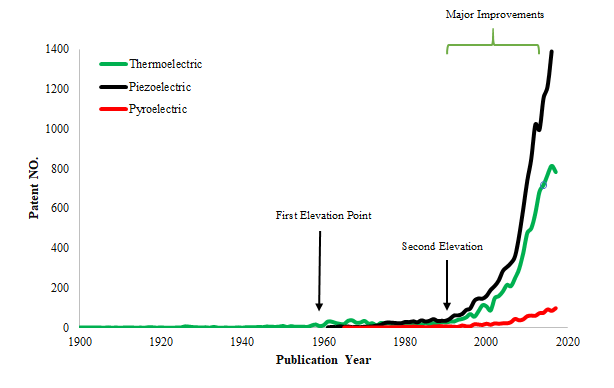

Patents in thermoelectric energy harvesting technology have been being published since 1900 (even before this year), hence, this technology is considered the oldest. After which, piezoelectric and pyroelectric energy harvesting technologies initiated publishing patents. The former started in 1961 and the latter started in 1965. Moreover, the publication trends for these technologies have been progressively increasing where in recent years their figures are elevating exponentially (after 1990). This remarkable elevation in the publication trends could be due to several factors namely energy crisis which caused the inevitability of working on renewable energies, need for self-powered systems, the advent of printed electronic especially wearable smart devices (WSDs) and so on.