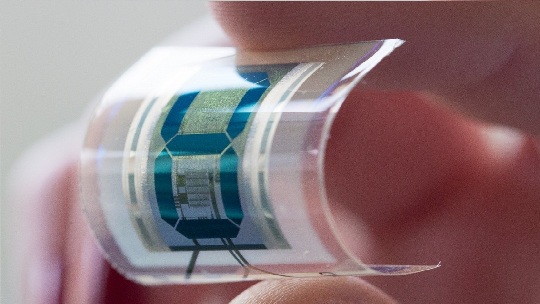

Printing sensors and electronics over flexible substrates are an area of significant interest due to low-cost fabrication and possibility of obtaining multifunctional electronics over large areas. Over the years, a number of printing technologies have been developed to pattern a wide range of electronic materials on diverse substrates. As further expansion of printed technologies is expected in future for sensors and electronics.

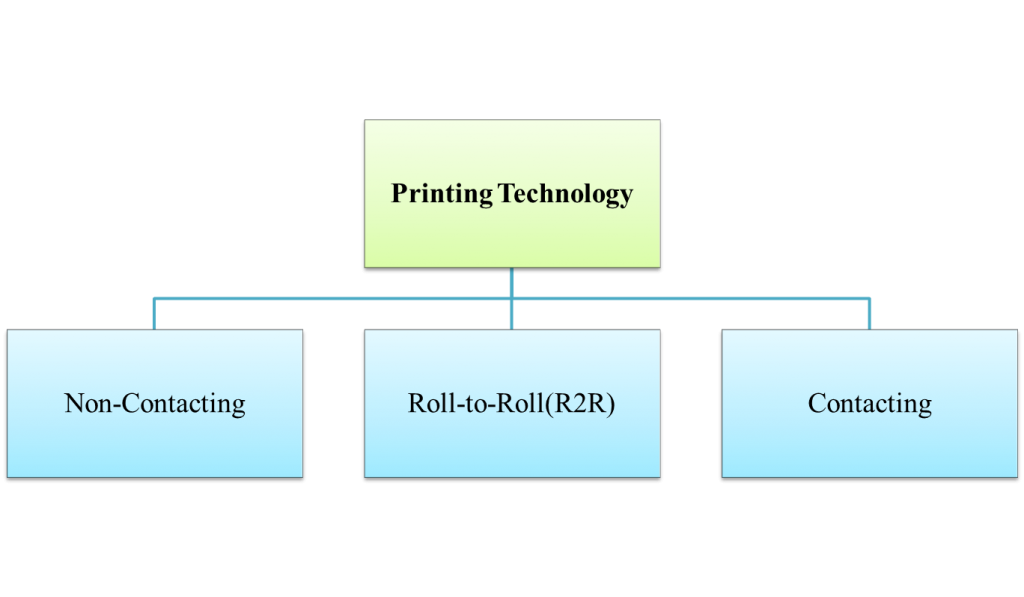

This article presents a comprehensive review of various printing technologies, commonly used substrates and electronic materials. Various solution/dry printing and contact/noncontact printing technologies have been assessed on the basis of technological, materials, and process-related developments in the field. Critical challenges in various printing techniques and potential research directions have been highlighted. Possibilities of merging various printing methodologies have been explored to extend the lab developed standalone systems to high-speed roll-to-roll production lines for system level integration.

Printed sensors and electronics have attracted greater interest as printing enables low cost fabrication. The increased number of research articles and demonstration of printed sensors and electronics in a number of applications reflects the keen interest of the researchers in their quest

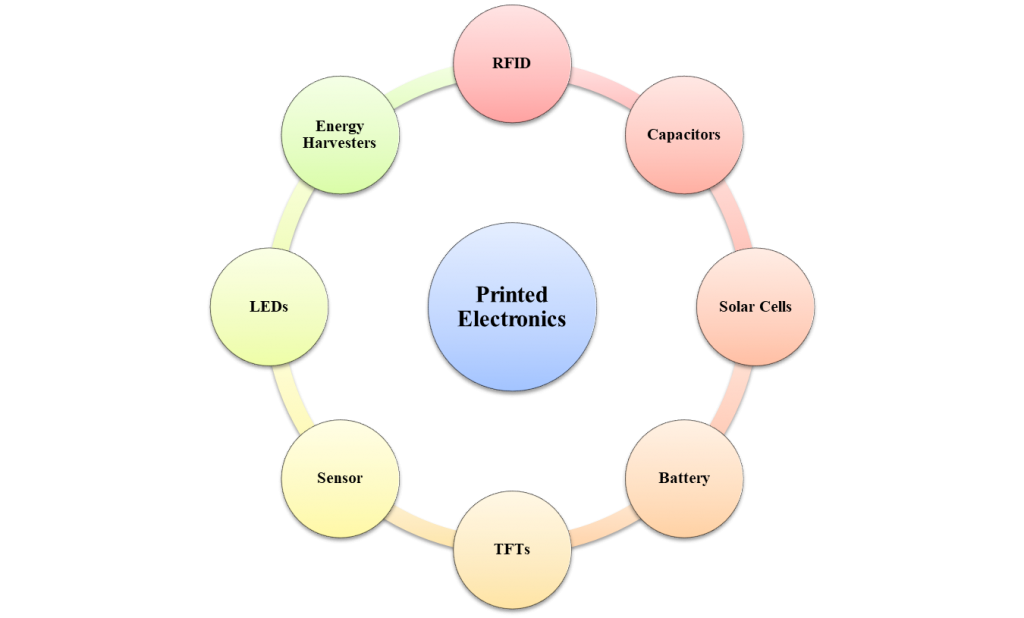

to fulfill the promise of large area electronics on flexible substrates through cost-effective printing technologies. We have investigated patents and have exhibited a comprehensive overview of various technologies that have been employed so far for the printed devices in the following figure.

Material solutions with adjusted rheological properties and optimum processing parameters are the major paradigms for current research on printed electronics. Most of the existing printing technologies use solution based organic materials, which often result in transistors with modest

performance, which is suitable for low end applications such as RFID and displays. The performance of printed devices is also affected by the resolution limits of current printing

technologies, which is much poorer than possible with current micro/nanofabrication tools. For fast communication and computations in emerging areas such as internet of things (IoT) will require cost-effective electronics with high-performance. Recent progresses with printing of high-mobility materials holds a great promise for the high-performance printed electronic systems. Advances in dry transfer printing of inorganic materials could complement the organic materials based solutions. A possible approach is to employ stamp printing techniques for high-mobility semiconductor material (both solution and solid state) deposition and exploiting

conventional printing technique for interconnects and metallization. However, due to resolution limits of current printing tools the full potential of printing has not been realized. Printing of high-mobility materials with resolutions comparable with the current micro/nanofabrication tools will be a significant step towards cost-effective high-performance electronic systems. The hetero-integration, involving devices based on both organic and inorganic materials, is another

interesting area that could lead to stable electronic systems with good mechanical, chemical and electrical properties. The printed devices and circuits demonstrated in labs often use standalone printing technologies.

For large scale production, there is a need to scale or merge these printing technologies on R2R production lines without sacrificing the chemical, physical or electrical characteristics of the device. The large area electronics through R2R production lines is foreseen to play a major role in the cost-effective manufacturing of nonconventional electronic devices and systems. Development of an efficient platform by assembling different coating, printing and patterning tools to develop a very robust process protocol will result in high throughput and low cost devices. Following the trends of paper printing industry, the manufacturing cost of plastic electronics is expected to reduce by the fast speed printing of electronic components at defined locations. The cost-effectiveness of printing technologies and employing them for flexible electronics will enable new classes of applications, and dramatically change the electronics industry landscape. Printed electronics and sensing will also have a major societal and economic impact with skilled labor from print industry gradually developing printed electronics.