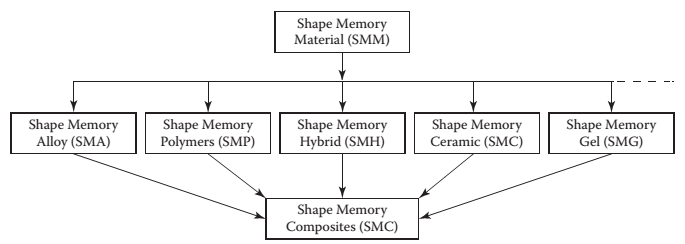

Shape-memory materials (SMMs), also sometimes known as smart materials, are distinguished by their capacity to recover a predetermined shape after a remarkable mechanical deformation under different alterations such as temperature.

SMMs have been extensively developed and applied in smart structure technology. The term “memory” refers to the ability of SMM to regain the trained shape from a deformed shape in response to specific external stimuli (eg. heat). Shape memory alloy (SMA) and shape memory polymer (SMP) are two types of most commonly used SMM’s.

The SMPs are capable of being programmed to fix in a deformed state and then recover to the original state through exposing to an external stimulus comprising the heat, pH, light, electricity, microwaves, pressure, solvent, etc.

The SMPs are of the advantageous of lower densities, larger strains, bigger range of tailorable temperatures, easier processing, biocompatibility and biodegradation, and lower cost, which paved the way for their applications in various areas such as textiles, aerospace technologies, biomedical applications, and smart actuators, etc.

Unlike shape memory alloys, SMPs exhibit a radical change from a normal rigid polymer to a highly flexible elastic polymer and then quickly revert back on actuation by application of heat.

The SMPs also depict a promise for being used as minimally invasive medical materials. The SMPs can be processed into the geometries of highly porous and ultra-low density foams. A group of SMPs have been suggested for the medical applications, among which the polyurethanes (PUs) are of deep interest owing to their excellent biocompatibility.

From the mechanism perspective, the SMPs differ from the SMA’s, that are based on the martensitic transformation. SMA possesses the memory ability due to reversible phase transformation between the low temperature martensite phase and the high temperature austenite phase. In other words, the stress-induced strain on SMA can be recovered by heating the SMA up to the austenite finish temperature by transforming the low stiffness martensite phase to the high stiffness austenite phase.

Encountering a constraint in the shape recovery, these alloys promote the high restitution forces. Despite the fact that a wide range of alloys own the shape memory effect, only some of them with strain recovering or restitution force-generating properties are of commercial interest. Although a wide range of shape-memory alloys (SMA’s) are available, NiTi, CuZnAl and CuAlNi are the most popular in terms of their performance indexes.

Shape-memory polymers (SMPs) are superior to SMA’s in many respects. For instance, they are easily processable, cost-effective and lighter, and possess greater recoverable strain. Moreover, they are various stimuli-responsive and their material properties can easily be tuned.

Challenges and Prospects

Though extensive investigations on various aspects of SMEs in SMPs have been done by researchers, quite a number of issues still remain unresolved and unsettled. SMPs have unlimited application potential, but several factors restrict their practical applicability. The relatively poor mechanical properties, low recovery stress, long response time, lower cyclic life, weak material stability, etc., of SMPs are some of the serious obstacles for their broad application.

Another important area of concern is the control of SME in biological systems, where simultaneous occurrences of several complex issues flexible mechanical constraints, metabolic activities, complex chemical environment, etc.—should be properly addressed.

Nevertheless, Shape-memory implant materials would have a decisive influence in designing the medicinal products, in the future. Bio-inspired SMPs that mimic intelligent nature materials is another potential area of future research.